Bioprocessing-inspired Water-Mediated Crystallization and Densification of Strong Nacre-Like Aragonite Ceramic from Hydrated Amorphous Precursor

Bioprocessing-inspired fabrication of strong nacre-like aragonite ceramic

Bioprocessing-inspired fabrication of strong nacre-like aragonite ceramic

In February 2025, Professor Zhaoyong Zou and Professor Zhengyi Fu’s team from the State Key Laboratory of Advanced Technology for Materials Synthesis and Processing at Wuhan University of Technology published a research article titled “Bioprocessing-inspired Water-Mediated Crystallization and Densification of Strong Nacre-Like Aragonite Ceramic from Hydrated Amorphous Precursor” in Advanced Functional Materials.

1. Research Background

Ceramics have widespread applications in many fields. However, they are typically fabricated by powder sintering at temperatures exceeding 1000 °C, resulting in extremely high energy consumption. In contrast, living organisms can synthesize dense biominerals, such as tooth enamel and mollusk shells, under mild ambient conditions. Furthermore, biominerals often exhibit an excellent combination of conflicting mechanical properties, such as high stiffness and high toughness. Therefore, drawing inspiration from biomineralization processes offers a pathway to fabricate ceramics with excellent mechanical properties at low temperatures or even room temperature.

One of the most common strategies utilized by organisms is the use of amorphous phases as precursors to produce dense biominerals. For instance, sea urchins construct their spicules by depositing hydrated amorphous calcium carbonate (ACC) at the growth front, followed by dehydration to anhydrous ACC and subsequent transformation into calcite crystals. Mollusks also use ACC as a precursor to build their nacreous shells.

Inspired by these biogenic processes, the team designed a novel fabrication method for aragonite ceramic. This method involves the in situ crystallization and densification of hydrated ACC under pressure at a relatively low temperature (80 °C). Mechanism studies revealed that water released from hydrated ACC upon dehydration facilitates the nucleation of aragonite nanocrystals and further densification. Moreover, by introducing cellulose films as organic interlayers, nacre-like aragonite ceramics with an excellent combination of high hardness and toughness were obtained.

2. Research Content

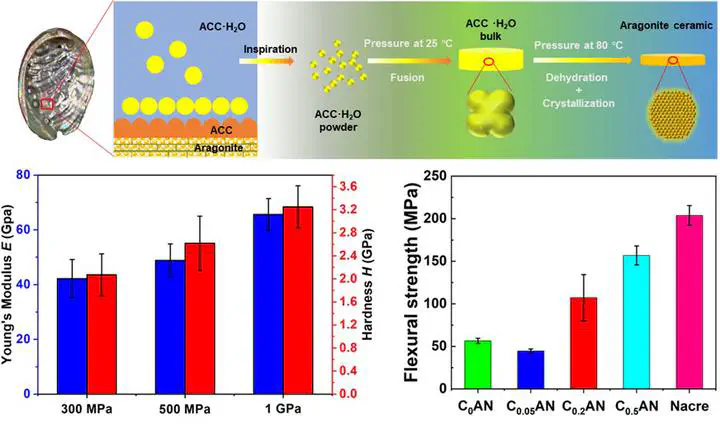

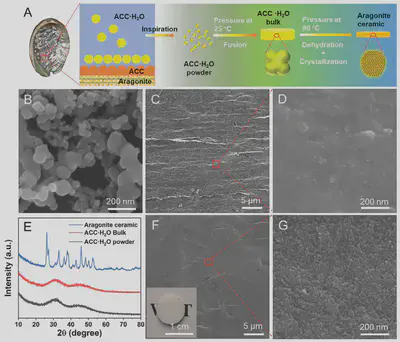

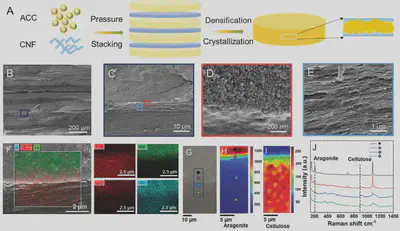

As illustrated in Figure 1A, the nacre formation process begins with the deposition of a layer of hydrated ACC nanoparticles, which subsequently dehydrate into anhydrous ACC and then transform into aragonite nanocrystals. Inspired by this process, bulk aragonite ceramic was prepared using amorphous nanoparticles as the starting material. Stable hydrated ACC nanoparticles with an average diameter of ≈80 nm were synthesized (Figure 1B). Under a pressure of 1 GPa at 25 °C for 4 hours, these nanoparticles densified into an integrated bulk material through particle fusion, where structurally bound water within the amorphous nanoparticles promoted mass transportation (Figure 1C,D). XRD patterns confirmed the bulk material remained amorphous (Figure 1E). Subsequently, the ACC bulk was heated to 80 °C while maintaining pressure, inducing its transformation into crystalline aragonite (Figure 1E). The resulting aragonite ceramic had a relatively smooth fracture surface, composed of densely packed nanoparticles less than 20 nm in diameter (Figure 1F,G).

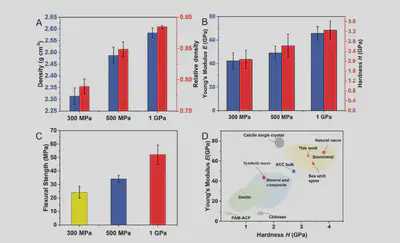

The density of the aragonite ceramic increased with applied pressure, reaching ( 2.58 \pm 0.02 \text{g cm}^{-3} ) (88.4% relative to geological aragonite) under 1 GPa (Figure 2A). Nanoindentation tests revealed that the hardness and Young’s modulus also increased with pressure, reaching ( 3.25 \pm 0.37 \text{GPa} ) and ( 65.65 \pm 5.77 \text{GPa} ), respectively, under 1 GPa (Figure 2B). The flexural strength was ( 52.15 \pm 7.19 \text{MPa} ) (Figure 2C). The hardness and modulus of the aragonite ceramics were comparable to those of natural nacre and sea urchin spines and significantly higher than other mineral-based composites, including synthetic nacre (Figure 2D).

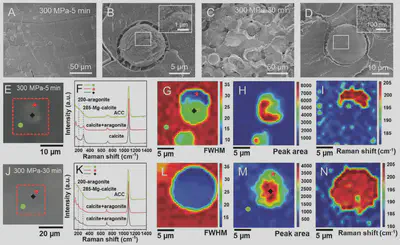

The crystallization mechanism was investigated using SEM and confocal Raman microscopy. Under 300 MPa at 80 °C, numerous microspheres (5–10 μm in diameter) appeared on the fracture surface after 5 minutes (Figure 3A,B), containing both calcite and aragonite as confirmed by Raman spectroscopy (Figure 3E,F). These spheres grew larger (20–30 μm) after 30 minutes (Figure 3C,D), with aragonite becoming the dominant phase. Raman mapping showed that crystallization began with the nucleation of Mg-calcite, followed by aragonite formation around the calcite cores (Figure 3G-I, J-N). Higher pressures delayed crystallization but promoted aragonite formation over calcite.

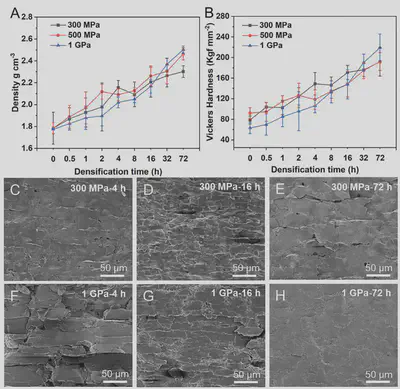

The densification process was monitored by measuring density and hardness over time. The density gradually increased (Figure 4A), and Vickers hardness showed a positive correlation with density (Figure 4B). SEM images of the fracture surface revealed that the initially layered structure with pores (Figure 4C,F) gradually fused, reducing porosity over time. After 72 hours at 1 GPa, the layered structure was eliminated, resulting in a homogeneous, dense microstructure (Figure 4E,H).

To further improve toughness, carboxylated cellulose nanofiber (CNF) layers were introduced into the ACC before crystallization and densification, creating a cellulose-incorporated artificial nacre (CAN) with a hierarchical architecture (Figure 5A,B). SEM and EDS mapping confirmed good interfacial bonding, with CNF partially infiltrating the aragonite layer, forming a continuous ≈2 μm interface (Figure 5C-F). Raman mapping confirmed the coexistence of cellulose and aragonite at the interface (Figure 5G-J).

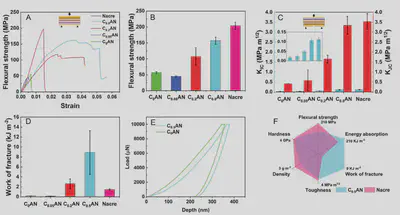

The mechanical properties of CAN were significantly enhanced. The flexural strength of C~0.5~AN reached ( 156.85 \pm 11.23 \text{MPa} ), about three times that of the ceramic without cellulose (C~0~AN) (Figure 6A,B). Its fracture toughness reached ( 3.35 \pm 0.45 \text{MPa·m}^{1/2} ), comparable to natural nacre (Anodonta woodiana, ( 3.54 \pm 0.39 \text{MPa·m}^{1/2} )) (Figure 6C). The work of fracture for C~0.5~AN was ( 8.88 \pm 4.38 \text{kJ m}^{-2} ), much higher than that of C~0~AN and nacre (Figure 6D). Nanoindentation showed the hardness and modulus of C~0.5~AN were ( 3.76 \pm 0.30 \text{GPa} ) and ( 63.38 \pm 6.67 \text{GPa} ), respectively, similar to the pure ceramic, indicating the organic layer did not compromise hardness (Figure 6E). The C~0.5~AN successfully integrated high strength, stiffness, hardness, and toughness into a single material with relatively low density (Figure 6F).

3. Summary and Outlook

Inspired by biomineralization, this work developed a low-temperature fabrication strategy for strong, dense ceramics using water-containing metastable amorphous materials as precursors. Aragonite ceramic with high mechanical properties was obtained through the in situ phase transformation and densification of hydrated ACC at a relatively low temperature. Raman mapping analysis elucidated the crystallization and densification mechanisms, highlighting the critical role of water in promoting nanoparticle fusion, aragonite nanocrystal nucleation, and further densification. By introducing a nacre-like structure and cellulose into the aragonite ceramic, the mechanical properties of the resulting CAN composites were further enhanced, rivaling natural nacre in both quasi-static and dynamic mechanical performance. Notably, the nanoindentation hardness and Young’s modulus reached 3.76 and 63.38 GPa, respectively, while macroscopic mechanical analysis yielded a Vickers hardness of 258.26 Kgf mm⁻² and a Young’s modulus of 5.94 GPa. The flexural strength and fracture toughness reached 158.0 MPa and 3.35 MPa·m¹/², respectively. This work provides new insights into the room-temperature preparation and densification technology for ceramics.

This work was supported by the National Key Research and Development Program of China (2021YFA0715700), the Program for Science and Technology Innovative Research Team of Hubei Province, the Hubei Provincial Natural Science Foundation of China (2024AFA002), the National Natural Science Foundation of China (52402351), and the China Postdoctoral Science Foundation (2023TQ0254).

Huifeng Hu, a 2021 Ph.D. student at Wuhan University of Technology, is the first author of the article. Professor Zhaoyong Zou and Dr. Qihang Wang from Wuhan University of Technology are the corresponding authors.

Publication Information: Huifeng Hu, Qihang Wang,* Huailing Gao, Pengfei Wang, Hang Ping, Jingjing Xie, Zhengyi Fu, and Zhaoyong Zou*, Bioprocessing-inspired Water-Mediated Crystallization and Densification of Strong Nacre-Like Aragonite Ceramic from Hydrated Amorphous Precursor. Advanced Functional Materials, 2025, 2421628.